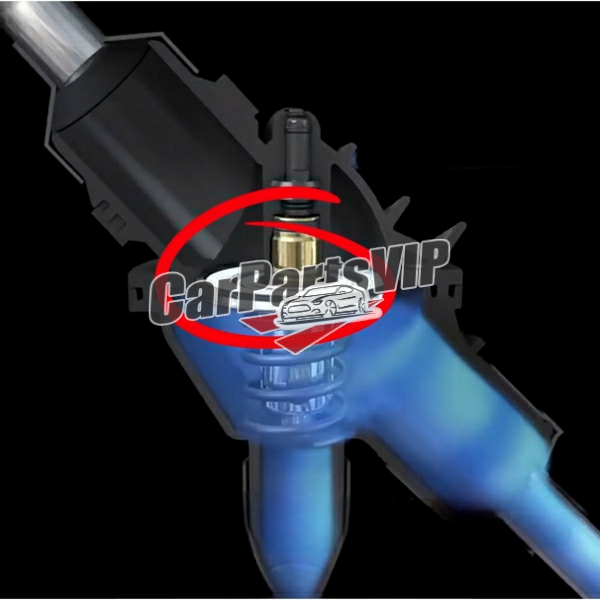

In the engine cooling system, the element that controls the flow of coolant is called a thermostat. The thermostat is a temperature-controlled valve that can automatically adjust the opening and closing of the valve according to the engine load and the temperature of the coolant to control the flow of the coolant to achieve large and small cycles. In layman’s terms, the thermostat is a three-way valve, one side of which is connected to the engine water outlet, one side is connected to the water inlet of the water pump, and one side is connected to the radiator. It can adjust the direction of the water flow according to the water temperature. When the water temperature is low, the coolant flows downward to achieve a small cycle; when the water temperature is high, the coolant flows upward to achieve a large cycle. It is usually installed in the engine water circuit to control the engine temperature. The engine mainly uses paraffin thermostats, which use the thermal expansion and contraction characteristics of paraffin to open and close the valve. Paraffin thermostats are divided into two categories: mechanical and electronic. Their implementation principles are the same, but the difference lies in the different trigger mechanisms of paraffin heating. First, let’s look at the mechanical thermostat. Let’s look at its components. It is a container, and the substance inside is paraffin. At low temperatures, paraffin becomes solid. Under the action of the spring, the thermostat valve closes the coolant channel between the engine and the radiator. The coolant returns to the engine through the water pump for a small cycle in the engine. At high temperatures, the paraffin melts and expands and gradually becomes liquid. The volume increases and compresses the rubber tube to shrink. While the rubber tube shrinks, it pushes the push rod upward. The push rod pushes the valve downward to open the valve. At this time, the coolant passes through the radiator to the thermostat valve and then circulates through the water pump to the engine for a large cycle. The main valve, return spring, base, lower bracket, bypass valve spring, bypass valve and other components form a whole and are sealed in the thermostat air shell. The base and lower bracket are fixed and play a fixing role. They cannot move during operation.

The linkage effect of the mechanical thermostat: The thermostat is held upward by the return spring and fixed to the base by the push rod passing through the piston. At low temperatures, the main valve and the base are sealed, and the bypass valve below and the wall of the sewer pipe are open. At this time, the coolant enters and exits to form a small cycle. When the temperature rises, the paraffin begins to melt and expand, and the piston will be pushed upward under the action of the expansion tension. Since the piston is fixed by the push rod and cannot move, the thermostat will be forced to move downward under the action of the reverse thrust. The thermostat moves downward under the action of the reverse thrust. At this time, the main valve is separated from the base, resulting in a certain opening, and the bypass valve below is combined with the wall of the sewer pipe to produce a certain degree of closeness. Since the water temperature at this time has not reached the peak value of the thermostat, the main valve above and the bypass valve below are not fully opened and closed, so the coolant will flow in two directions. At this time, the large and small cycles work at the same time. When the water temperature continues to rise and exceeds the thermostat peak, the main valve will be fully opened and the bypass valve below will be fully closed. At this time, all the coolant will flow through the main valve to the radiator and enter a full circulation mode. The above is the implementation principle of the mechanical paraffin thermostat.